For the longest time I've wanted to build a capacitive discharge spot welder for battery tabs. One problem being is that I couldn't afford or find suitable capacitors. Building one with new capacitors costs way more than I'm willing to pay for what in reality is just an experiment. So you can imagine my joy when I got a whole box of capacitor banks completely for free! Yes, whole capacitor banks. These come from forklift motor drivers that blow up beyond repair. The drives that these banks came from have their capacitors on a separate board, making it super easy to pull them out and use on something else.

These banks consist of 30 electrolytic capacitors that are rated for 63V and 680µF each and are all connected in parallel in a large capacitor bank. Each bank has two plates bolted to it that each serve as output terminals and have aluminum blocks on them with M8 tapped holes, ready to bolt to. In total this comes to just over 20mF of capacitance and at 60V it would hold about 36J of energy. To make a spot weld on a battery tab you are looking at about 50J of energy required, so two of these banks should be enough to cover that requirement and varying the voltage, to which the bank is charged to, should allow me to adjust the weld energy. Well that is the theory.

Capacitive discharge implies that there is a devide which discharges the capacitor. In this case it would be a semiconductor device. Most popular options are beefy SCR modules, that are great because they are self sustaining and turn off when the capacitor bank is discharged. To trigger them you need barely an impulse of curent and the rest they do by themselves. That makes them perfect for these applications and I did not use them in mine. Why? They're simply hard to find sometimes. On the other hand, you know what wasn't hard to find? A bag of 75N75 MOSFETs that I had ordered ages ago and that have been waiting for their time to shine. The plan was simple - I make a large MOSFET bank and use it to dump the capacitor energy into my weld area.

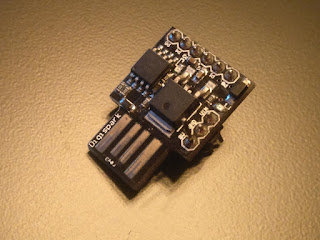

The construction was rather simple. Most of my time building it was consumed by all the holes I had to drill. Two aluminum plates were used as the bus bars for the weld current. The MOSFETs are mounted to these simply with M3 bolts. Everything is mounted on an FR4 board that has two score lines in it, to separate the copper layer into three strips - the gate, source and drain connections for the MOSFETs. Each gate was connected to the gate strip with a low value resistor, simply to act as a fuse in case one blows up, and a discharge resistor was added to make sure the gates don't stay floating. The brick of MOSFETs was then connected to my capacitor bank and a simple SR latch gate driver was built to let me drive the gates high and low cleanly. This entire time I also had to keep in mind that MOSFETs are not SCR's and they will not turn off once current is done going through them. Meaning that if I forget to turn them off and try to touch my welding probes on the nickel strip I will get a shower of sparks as my capacitors discharge violently into the less than perfect contact that I would make in that moment. Oh the foreshadowing...

The setup was a bit janky as you can see clearly, but it did work. And by "work" I mean it didn't blow up. Of course the important question is whether it made a weld or not. And the answer is yes, it did! It perfectly welded my electrodes to the nickel strip.....wait a minute.

Sooooo yeeeeaaah, this is where the learning stage begins for me. As it turns out the peak current is way too high for this kind of application. When the caps discharge the peak current is enough to melt my copper probe tips and weld them to the nickel strip, without even harming the second strip underneath not one bit. To make sure that this was indeed the case, I tried measuring the current going through my circuit. For that I used the 16mm² as a current shunt, which conveniently has about 100µΩ per 10cm of wire. I then marked out two points 10cm apart from each other and tapped in two nails to clip my scope probes onto.

Once the waveform was capcured I was able to measure the peak voltage, which was about 1.2V and on a 100µΩ shunt that means I'm pushing a peak current of 12000A, that's 12kA! You don't often get to use numbers like these when describing your projects, unless it's about them blowing up. In a display of irony the current curve on the scope resembles the Dunning-Kruger effect and by this point I was sliding down that curve like a snowboarder down a mountain. The negative dip in current is caused by approximately 500nH of inductance.

So what can I do now? The capacitor bank has enough energy to make a weld but it's not working right. It all comes down to efficiency. The current pulse is way too short to heat the nickel strip enough to weld together. The copper electrodes weld just fine because they're the primary current carrier and have a tiny contact patch, which both melts and ablates, which makes them stick to the nickel. To lenghten the current pulse would require me to have a higher capacitance and lower voltage, so that I could have the same energy, but a lower voltage to dump the current slower. This is possible, but no longer seems like that great of an idea, simply because the bank of capacitors would become huge. And at that point it's not really that much better than just having a single MOT.

Some simple simulations on LTspice showed me that adding an inductor would prolong the current pulse and reduce the peak current. Which makes sense, because inductors resist the change of current. It's kind of like a brake on the current rise. And unlike a resistor, the inductor would not lose the energy. Of course in real life and with currents as high as what I was getting, the resistive losses even in thick copper wire are very significant. So I tried adding a coil of wire in series, which was wound on a 30mm mandrel with about 7 turns. It did change the welding characteristicts a little bit but they were not significant enough to make a difference in the weld. Adding metal into the center of the coil would not change the performance at all. Seems like the inductor idea was not the miracle cure that would fix all my problems.

So for now the project got put away and lives in a plastic box in the dark until I find a reason to pull it out again. I'll have to mention that all tests were done at 30V of capacitor change, because that's as high as my power supply would go. So there is potential to increase the energy of the capacitor bank by four times just by doubling the voltage. But that's for later. Now I have other projects to finish, before I let myself be distracted by this one again.

So that's it for now. Thanks for visiting my blog.

Komentarai

Rašyti komentarą