Quick thermocouple experiment.

After today's experiment with wicks I've found the perfect wick for my next experiment, but before that I need to prepare some more things. For my next experiment I'll need to be able to accurately measure the temperature of my heatpipe at both the cold and hot end. Since I'm all about DIY I thought the best way to measure the temperature would be to make myself some thermocouples. One easy way to make a thermocouple would be to create a junction between iron and copper. I want the mass of my thermocouple to be very small but I didn't have any thin iron wire, which is why I went looking for alternatives. One of them being NiChrome wire. As long as the junction consistsd of two dissimilar metals I can create a thermocouple. Creating the junction can be tricky, but I had the perfect solution for that - the electroplating solution. Since I've read somewhere that adding borax to your copperplating solution will help in creating a more uniform copper layer I added some into my electroplating jar. The idea was to create my copper-nicrome junction through the method of electrolating. 3 mA of current for about 15 minutes was enough to plate a 10 mm length of thin nichrome with a thick layer of copper.

The layer of copper was so thick, in fact, that it made the nichrome wire snap when I was twisting it together with my copper wire. I also copper plated the other end of the nichrome wire so that I'd be able to solder a wire to it. This created another copper-nichrome junction, which is far enough from my other junction that it should not have any significant effect on my measurements. The copper plated nichome was very easy to solder to and made for a strong connection with my copper wire.

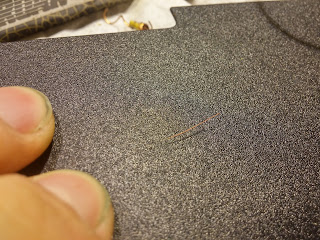

Before electroplating the nichrome was sanded with 2000 grit sandpaper to both clean and roughen the surface. You can see the copper plating cracking off if you zoom in on the picture above. The reason that the copper plating is cracking off there is because that part of the nichrome wire wasn't sanded.

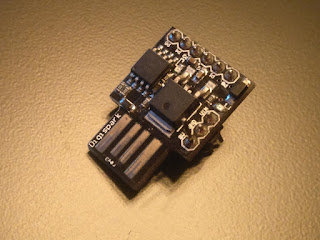

After my thermocouple was done it was time to test it. To do that I set my hot air station to 200C and the air at max and inserted my thermocouple into the nozzle. The voltage across the thermocouple reached 0.7mV. My mutimeter only reads down to 0.1mV, because of this in order to take a more accurate measurement an amplifier would have to me implemented. Considering all of the inaccuracies within this measurement the result can only be used as a ballpark. My thermocouple happens to land somewhere between type-B and type-S/type-R thermocouples.

That's it for now, thanks for reading.

Ps: the back of a laptop battery makes for a great background when taking high-res pictures.

The layer of copper was so thick, in fact, that it made the nichrome wire snap when I was twisting it together with my copper wire. I also copper plated the other end of the nichrome wire so that I'd be able to solder a wire to it. This created another copper-nichrome junction, which is far enough from my other junction that it should not have any significant effect on my measurements. The copper plated nichome was very easy to solder to and made for a strong connection with my copper wire.

Before electroplating the nichrome was sanded with 2000 grit sandpaper to both clean and roughen the surface. You can see the copper plating cracking off if you zoom in on the picture above. The reason that the copper plating is cracking off there is because that part of the nichrome wire wasn't sanded.

After my thermocouple was done it was time to test it. To do that I set my hot air station to 200C and the air at max and inserted my thermocouple into the nozzle. The voltage across the thermocouple reached 0.7mV. My mutimeter only reads down to 0.1mV, because of this in order to take a more accurate measurement an amplifier would have to me implemented. Considering all of the inaccuracies within this measurement the result can only be used as a ballpark. My thermocouple happens to land somewhere between type-B and type-S/type-R thermocouples.

That's it for now, thanks for reading.

Ps: the back of a laptop battery makes for a great background when taking high-res pictures.

Komentarai

Rašyti komentarą