Volvo ETM repair by retrofitting a BOSCH throttle position sensor.

My SAAB is currently not very drivable, so I opted to try out buying a Volvo. The one I sprung for is a second gen V70 with a turbocharged 2.4 liter engine that produces a pretty okay 184kW.

Yeah nah, it barely drives. Had I known Volvos were so unreliable I would have avoided these like the plague, but silly me has a problem to contend with now. This car is like a rabbit hole - the ETM will go bad, the PCV will go bad, the VVT pulley will go bad, the MAF will go bad, the gauge cluster will go bad, the fuel pump controller will burn out, the automatic gearbox sucks and the engine mounts tear out on a regular basis. And did I mention that the cam seals will just pop out and leak all your engine oil out in the engine bay? Yeah they do that. In my case I already had the seal pop out and my VVT pulley is on it's way out. But the bigger issue I had was the ETM failing, for which there is no easy fix. Used ETM's cost at least 100€ will come with the same problem and new ETM is 450€!

The problem with the ETM, as far as I know, lies in the throttle position sensor, which wears out prematurely and starts giving a messy signal, which then causes an ETM related error, poor running and sometimes no throttle response at all. And this has become such an issue that there's even a recall in the US. Unfortunately for me, I live in the EU and no recall was announced here so I'm left to my own devices. And my own devices I certainly do have but, before we get cooking, let's take a look at the ETM itself.

Once you pull the ETM out you have to pry off the aluminum cover on the side. To do this it helps to slice along the edge to cut the silicone sealant that's holding it in place. The aluminum cover is soft and thin so bending it is too easy.

And once you're in you are greeted by lots of hardened green gunk. Looks as if Shrek got a little too excited while assembling these. You'll need to cut and scrape it away to reveal the contacts that join the TPS with the ETM. But before that you'll need to know which TPS to uncover. Yes there are two and as far as I understand only one of them is important. Looking at the pic above it is the left side TPS that we want to remove. When the ETM is installed this TPS is pointed at the alternator. Which is quite unfortunate, considering if it were on the other side, you wouldn't have to remove the entire ETM to replace this sensor.

Once you clean the potting off you'll be greeted by three contacts. I don't know if these are soldered, but for now we are leaving these alone because the next step is to pull the TPS off. To do that you remove four torx screws, and then quite literally pull the TPS out. In the process you also detach the contacts.

The sensor gets a bit roughened up in this process, but we're replacing it anyways so who cares. But that lets us take a look inside and see how this thing is made. And the construction is quite interesting. Normally potentiometers rub on a flat plane, but here the resistive element is cylindrical. What's more, is that it's made of kapton material and is not held in place by anything except the crimp at the end. After cleaning the sensor up there does not seem to be any noticeable wear on the resistive element but there might me more to it than the eye can see.

So as I said we are replacing this TPS but with what? The only available replacement is the XeMODeX contactless TPS, which is hard to get and costs a lot. Besides that there really are no other options. But then you have to wonder if there's something inherently wrong with having a regular potentiometer based TPS? Surely other manufacturers would have the same problems with their TPS's? Actually no, it's only Volvo that screwed up this bad.

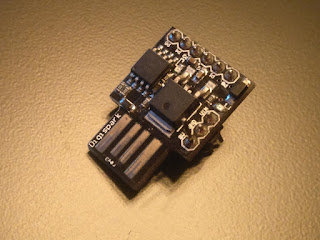

So you know what? I have a BOSCH TPS from my crashed SAAB (the other one) that I can put to good use, because it's actually reliable. And it just so happens that it's made for a shaft size that can be easily adapted to fit on the Volvo ETM shaft. What I'm talking about is that the diameter of the D shaft for the BOSCH TPS is 8mm and the Volvo TPS has a D shaft diameter of 6.5mm. The flat on both just so happens to align almost perfectly, so only a 0,75mm thickness spacer along the outer perimeter is needed to make the TPS fit on the ETM shaft. Of course the BOSCH TPS is nowhere near the same footprint as the original TPS, so it had to be adapted to fit. So let's design and 3D print an adapter.

To do that we take pictures of the Volvo ETM with a reference at the same plane. Any thing that has a known size can be used for the reference. Even the hole spacing on the ETM can be used as a reference. Along with it, the BOSCH TPS was also pictured with a reference. Multiple pics were made with the ETM and the BOSCH TPS at their maximum range both max and min, so that later I could measure this range and align both TPS and ETM ranges of movement with each other precisely.

The ETM and the TPS both have a working range of 89 degrees, so if the rotational range of both is not perfectly aligned they will bind at either the top or bottom of their range of movement. It should go without saying that this would lead to either or both being damaged so let's not do that.

After some work in Onshape I was able to make a 3D model for both the adapter plate and the shaft bushing for the Volvo ETM. After this I was able to print the model on an Ender 3 using PETG filament. Since this part will be in the engine bay and will get quite hot, plastics like PLA would just melt and fall apart. PETG should be able to hold shape for long enough to see if the concept works. Once the concept is proven I can print this part out of resin on my SLA printer. Hardened resin doesn't melt so it's perfect for applications like this.

The fit happened to be perfect, even though I never accounted for any clearance. I guess I just got lucky, or the plastic had enough give in itself to go in quite snugly without any looseness.

Next step was to attach the BOSCH TPS and see if it works right. What i was interested in the most was the voltage range of the TPS, because if it did not match what the original TPS was showing, then I would have to create some sort of circuit that adjusts this voltage to match, which is an additional hassle.

Fortunately for me the BOSCH TPS is a perfect fit in terms of voltage range. Originally the Volvo ETM will have 0,6V on the TPS when fully closed, 1.39V when idle and about 4.65V when fully open. Although the fully open voltage is not strictly critical. It is the fully closed and idle voltages that we need to match perfectly, otherwise the ETM will not work right. And my new TPS just so happens to fit that range perfectly. There was only the slightest offset, which was easy to eliminate by just slightly nudging the TPS alignment, since there was a little bit of room for movement.

Silly me forgot to bring the connector for the TPS, then it would have been replaceable. Because of that I had so solder the signal wires directly. Now how do I know which wires go where? There's a forum thread that shows which contacts do what on the Volvo ETM here:

https://www.swedespeed.com/threads/2001-v70-xc-etm-clean-or-replace-with-contactless-sensor.647452/

But the BOSCH TPS needed some light probing to see which wire goes where. Since it's just a potentiometer i just had to find the wiper contact and the rest I knew were the two ends that took GND and +5V. At first I had these connected backwards, but reversing them was easy enough. After this the ETM was fixed! No more defective TPS that wears out quickly and the TPS I used is easy to find and is widely used in many cars. Also it is proven to be reliable and is now easy to replace to boot. It only costs 30€ for a quality part and only 10€ for a knockoff.

Of course the proof of the pudding is in the eating and so I went to install my newly repaired ETM back into my Volvo. And did it work? Well yes it did. Although there are many more problems with my Volvo than just the ETM, the ETM error went away and did not come back, so I consider this mod a great success.

Now all that's left is to fix everything else in the car because Volvo does not believe in reliable electronics. SMH

Anyways, that's it for now and thanks for visiting my blog.

Komentarai

Rašyti komentarą