Homemade injection molded silicone heatblock sock leads to some new discoveries along a stinky surprise.

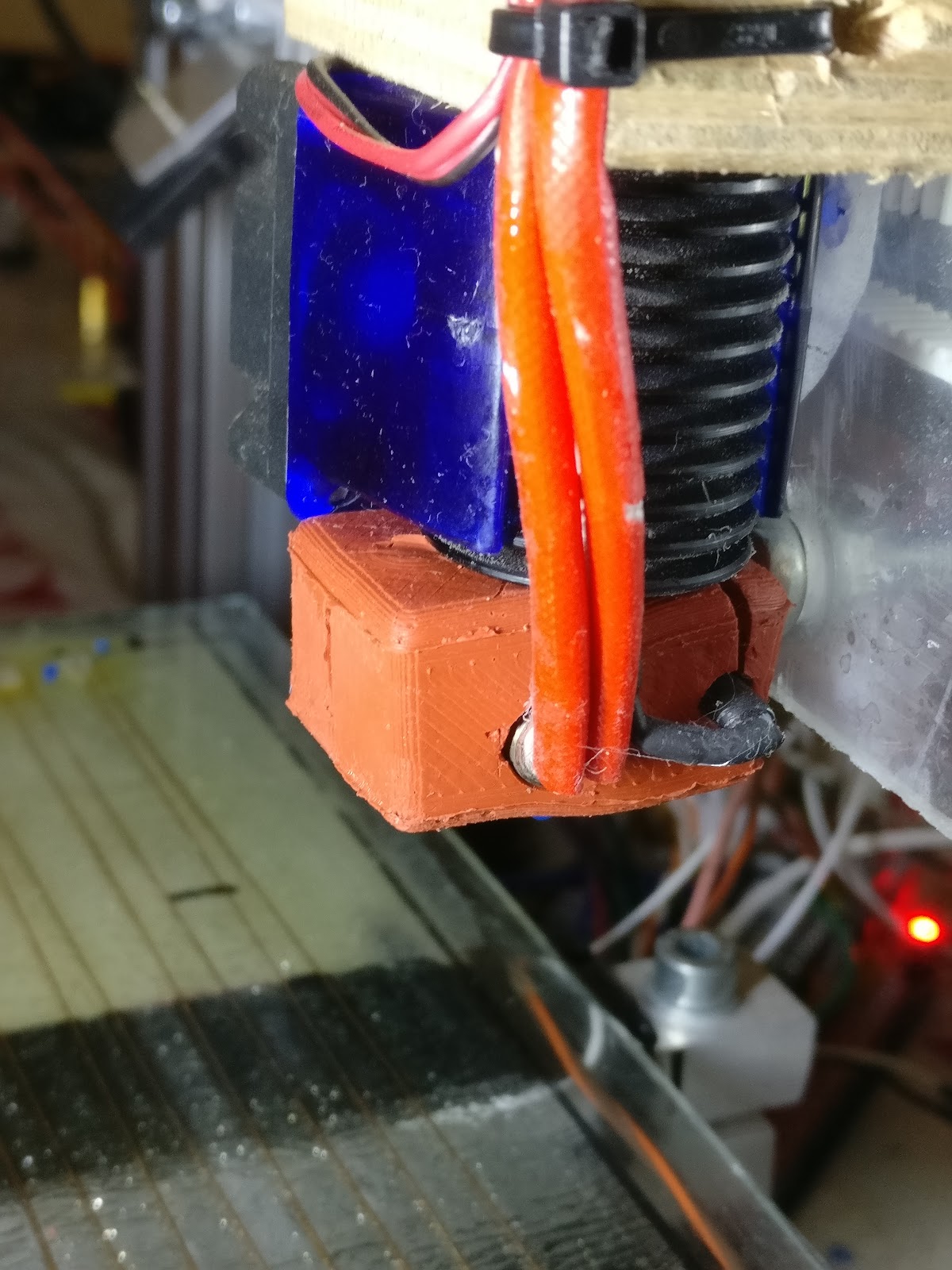

I'm using a clone of a E3D V6 hotend on my homemade 3D printer and it's having problems with stability. Part of that instability is caused by part cooling as it seems my hotend is only capable of handling only the slightest breeze, otherwise it can't can't keep up and my PID loop goes wild. So, inspired by Stefan from the CNC Kitchen YouTube channel, I decided to make my own.

Starting with the model of the block, I took a drawing of the heatblock I found online and made a copy of it in Fusion360. Then I created a new solid by offsetting the surface of the heatblock by 2mm, which is my desired thickness for the silicone sock. Then I cut out parts of the body where the nozzle, the heater and other components had to stick through, along with the holes for the screws. Next, the whole thing was placed in a block and a cavity within the block was created. After that the block was sliced into pieces and screw holes were added to clamp the assembly shut. Once the design was finished the mold was printed out in PETG. A single hole is left in the mold to inject material. No exit is needed because all air escapes through the gaps in between parts of the mold.

After that I noticed something. The silicone smelled like vinegar. Hmmmm...... Do you know how adding baking soda to vinegar releases gas? What would happen if I added some baking soda to the silicone before injecting? So that's what I did next and immediately after injecting I noticed the silicone starting to ooze out. After coming back to the mold after letting it cure I found out that the silicone expanded quite a bit.

After demolding I found out that the experiment was a success and the silicone did in fact expand and turn into a foam. It was also much softer than the solid silicone piece, as you would expect. Another thing I didn't think about is that the baking soda neutralizes the vinegar in the silicone so the foam no longer smells like vinegar, which is also great.

Next up was the heat test, because what's the point of the silicone sock if it can't handle the heat, right? So I confidently jumped straight into a print, because, as mentioned, the silicone I'm using is rated for up to 300C so some 215C printing temperature should work out just fine right? Well as it turns out not really. The silicone handled the heat just fine but it started offgassing and stank up the whole room. So unfortunately it's a bust in that aspect. Of course you might ask why not use proper silicone resin, but I don't have it. And if I don't have it then it's a thing I have to find, buy, pay for, wait for and it's something I'm not willing to do for a simple project like this, especially since high temperature silicone is expensive.

Komentarai

Rašyti komentarą