Homemade injection molded silicone heatblock sock leads to some new discoveries along a stinky surprise.

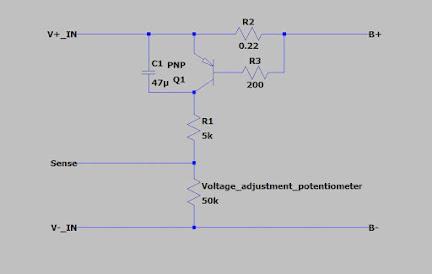

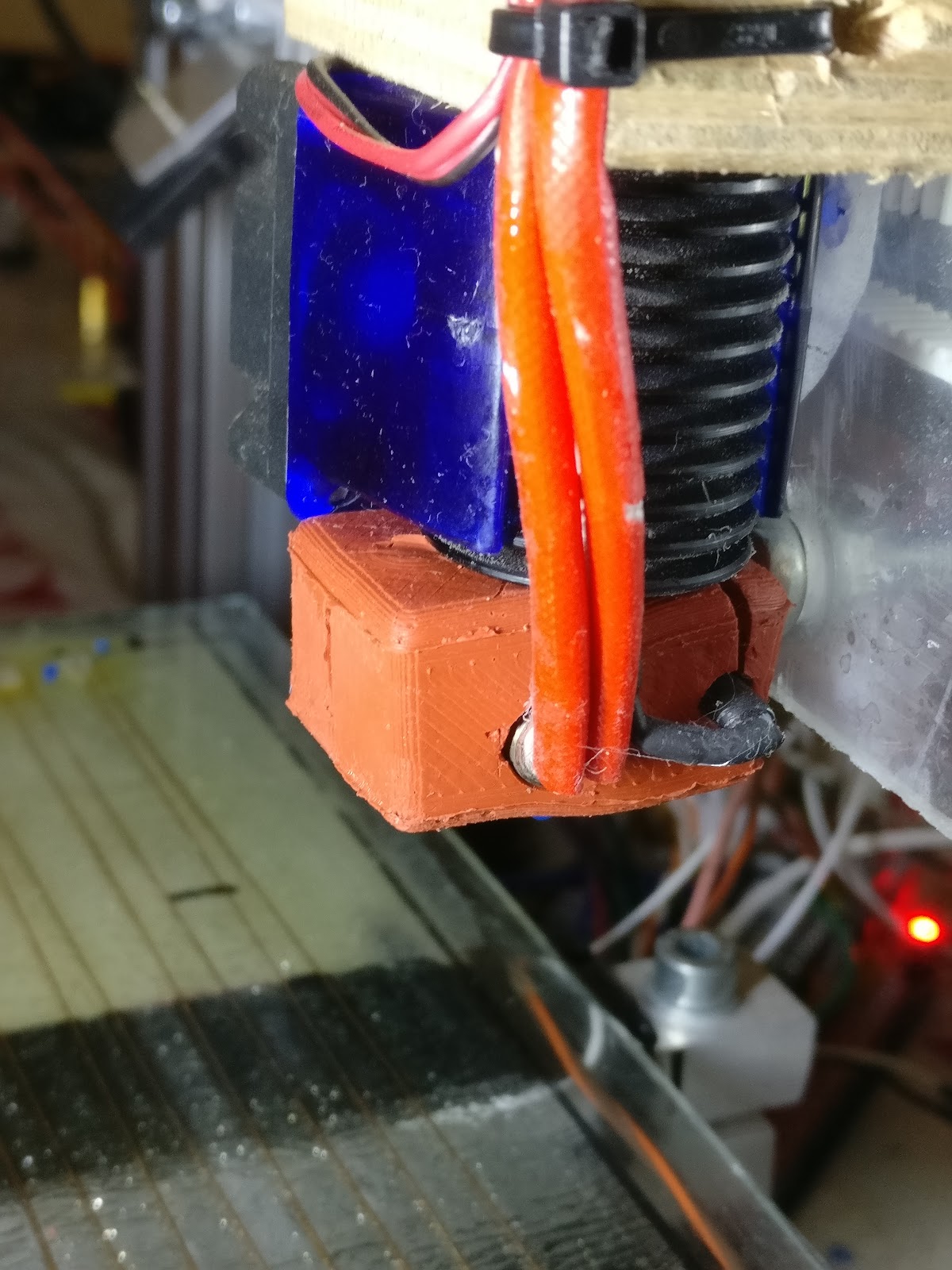

I'm using a clone of a E3D V6 hotend on my homemade 3D printer and it's having problems with stability. Part of that instability is caused by part cooling as it seems my hotend is only capable of handling only the slightest breeze, otherwise it can't can't keep up and my PID loop goes wild. So, inspired by Stefan from the CNC Kitchen YouTube channel, I decided to make my own. Starting with the model of the block, I took a drawing of the heatblock I found online and made a copy of it in Fusion360. Then I created a new solid by offsetting the surface of the heatblock by 2mm, which is my desired thickness for the silicone sock. Then I cut out parts of the body where the nozzle, the heater and other components had to stick through, along with the holes for the screws. Next, the whole thing was placed in a block and a cavity within the block was created. After that the block was sliced into pieces and screw holes were added to clamp the assembl...