Converting a power steering pump into a vacuum pump - the opening.

I've always wanted a high vacuum setup but Santa didn't leave one under my Xmas tree so I'll have to, you guessed it, DIY my own.

One of the easiest ways to obtain vacuum is with a refrigerator compressor. While refrigerator compressors do achieve some level of vacuum it's not real vacuum. The reason is that refrigerator compressors use pressure controlled valves that require pressure difference to keep them shut. In true vacuum the air molecules are no longer making contact with each other so you can no longer achieve a pressure differential, thus the reed valves in your fridge compressor no longer close and only a certain level of vacuum can be achieved. That's assuming your fridge compressor doesn't stop pumping even earlier than that. If the valves were to be controlled mechanically then a higher lever of vacuum could be achieved. One of the most popular types of vacuum pumps is a rotary vane pump. These have vanes that work as valves and since they're a part of the rotor assembly they also move and with the rotor and allow the pump to achieve high levers of vacuum.

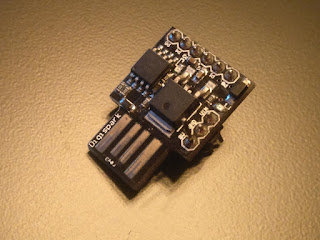

One problem with DIY-ing a rotary vane vacuum pump is that these pumps require a high level of precision to operate as a high vacuum pump. Since making one was not an option I went to look for alternatives. After all, why make one when someone else can make one for you? That's when I found an old power steering pump in my basement. I have no idea where the pump came from. I asked both my dad and my brother if they knew where the pump came from but they had no idea we even had one like this so as far as I'm concerned it's mine to keep. Before I took it apart I checked with google what these look like on the inside and most of these power steering pumps are in fact rotary vane pumps - sweet. The reason this pump caught my attention was that it was small and cylindrical. Since it pumps hydraulic oil at a high pressure and the only way it could do that in such a form factor was if it was a rotary vane pump was enough of a reason for me to pull it apart to check what the insides look like.

After a visual inspection of the pump I decided that the best way to open it would be through the rear because it looked like it had a retainer ring in there. The pump was quite rusty and the ring was embedded in the housing deep enough that I couldn't get anything behind it to pull it out. In the end I had to drill some metal out from behind the ring retainer to get something behind it to pry the thing out.

After I got the retainer out I was met with another conundrum - how does the end come off? The two dimples on the back and the two flat spots on the middle part fooled me into thinking that this part should unscrew. After a lot of whacking and trying to turn the end I noticed that it had only turned slightly and moved out a tiny bit. I then tried turning it the other way and it turned easily but stopped quickly. I kept turning the end back and forth in an effort to overcome this stop that was keeping me from turning the end all the way but as soon as I noticed that the end has moved out a bit I quickly realized that it's supposed to pull out. I then ground a few notches in the center bit to get a flat screwdriver under to pry the center bit up and after some prying the end piece was loose and could be pulled off by hand. And thus the time had come to confirm that this pump can be converted into a vacuum pump. *drum roll*

And there it is, some light scratches on the rotor but nothing to be worried about. The next step now will be to find out which channels go where. The vanes are pushed outside by pressure from the high pressure side of the pump, meaning that there is a channel from the output to the area behind the vanes - that's exactly what I want. Rotary vane pumps rely on oil to seal them. My plan is to have oil behind the vanes where the atmospheric pressure would force the oil through the gaps out into the chamber where the vacuum is thus providing lubrication and sealing the pump. The oil would then collect at the output where it would be forced back behind the vanes by the atmospheric pressure. TL;DR: I only need to make an oil catch can at the output and a small tube from it to the channel leading behind the vanes to turn this into a proper vacuum pump.

Sweet, so the next stage will be identifying the low/high pressure channels, modifying, cleaning and re-assembling the pump.

That's it for now, thanks for reading.

Komentarai

Rašyti komentarą